Page 4 of 26

Re: From FreeCAD To The Real World

Posted: Fri Dec 04, 2015 9:51 pm

by cox

Wow, missing the smell of hot plastic just looking at this. Well done.

Cant wait for the update

+1 for video

Re: From FreeCAD To The Real World

Posted: Thu Jan 21, 2016 3:24 pm

by A_3

Something simple, nozzle.

I apologize for the bad resolution оf photo, broken camera on a mobile.

Drawing is not done according to the rules, it shows only general dimensions...

Part is a test example for washing system, and the test was successful!

Re: From FreeCAD To The Real World

Posted: Sat Jan 23, 2016 10:01 pm

by triplus

Nice project.

P.S. CAD model, blueprint and an actual product.

Re: From FreeCAD To The Real World

Posted: Wed Feb 03, 2016 9:58 pm

by JMG

Hi.

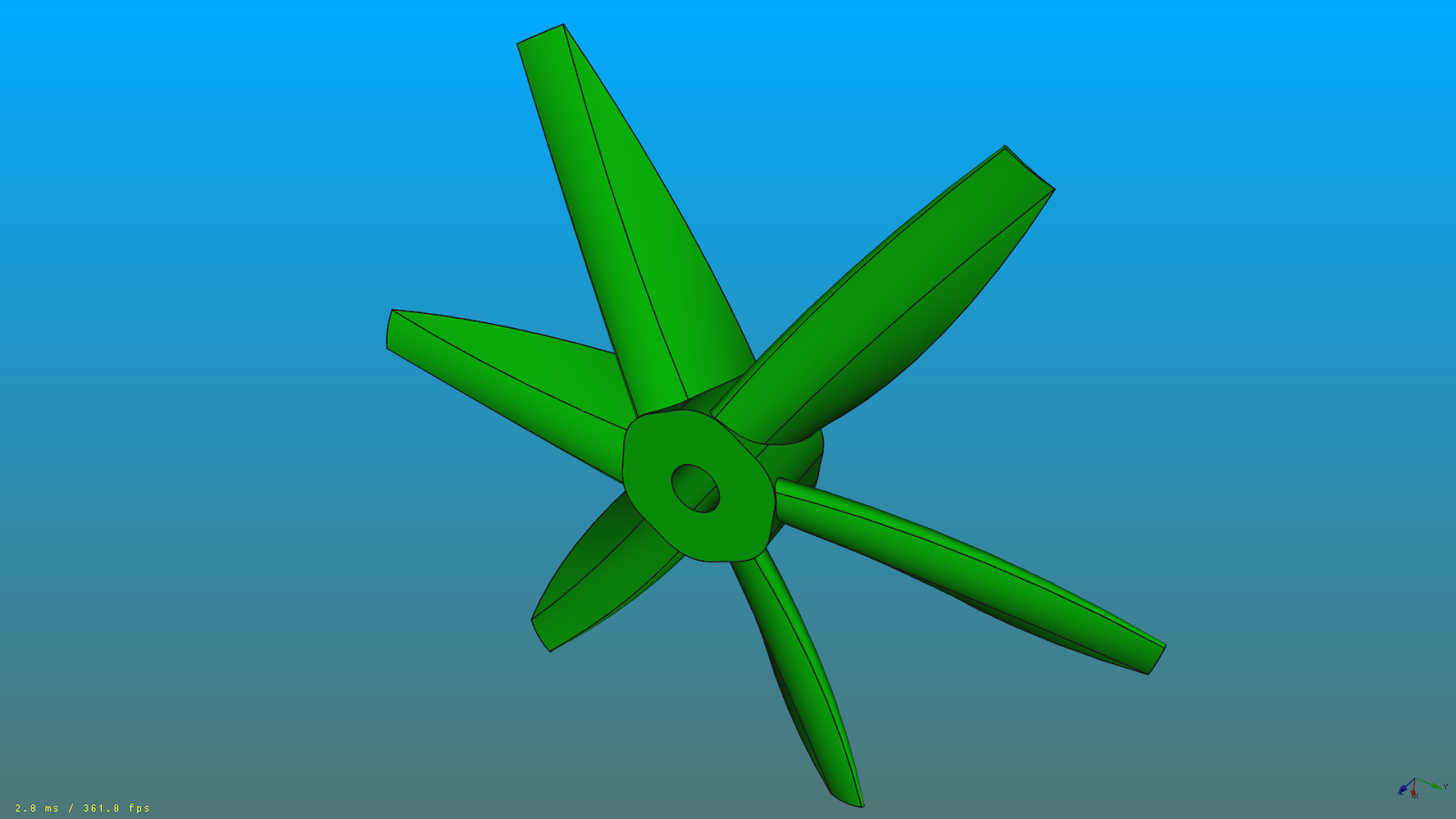

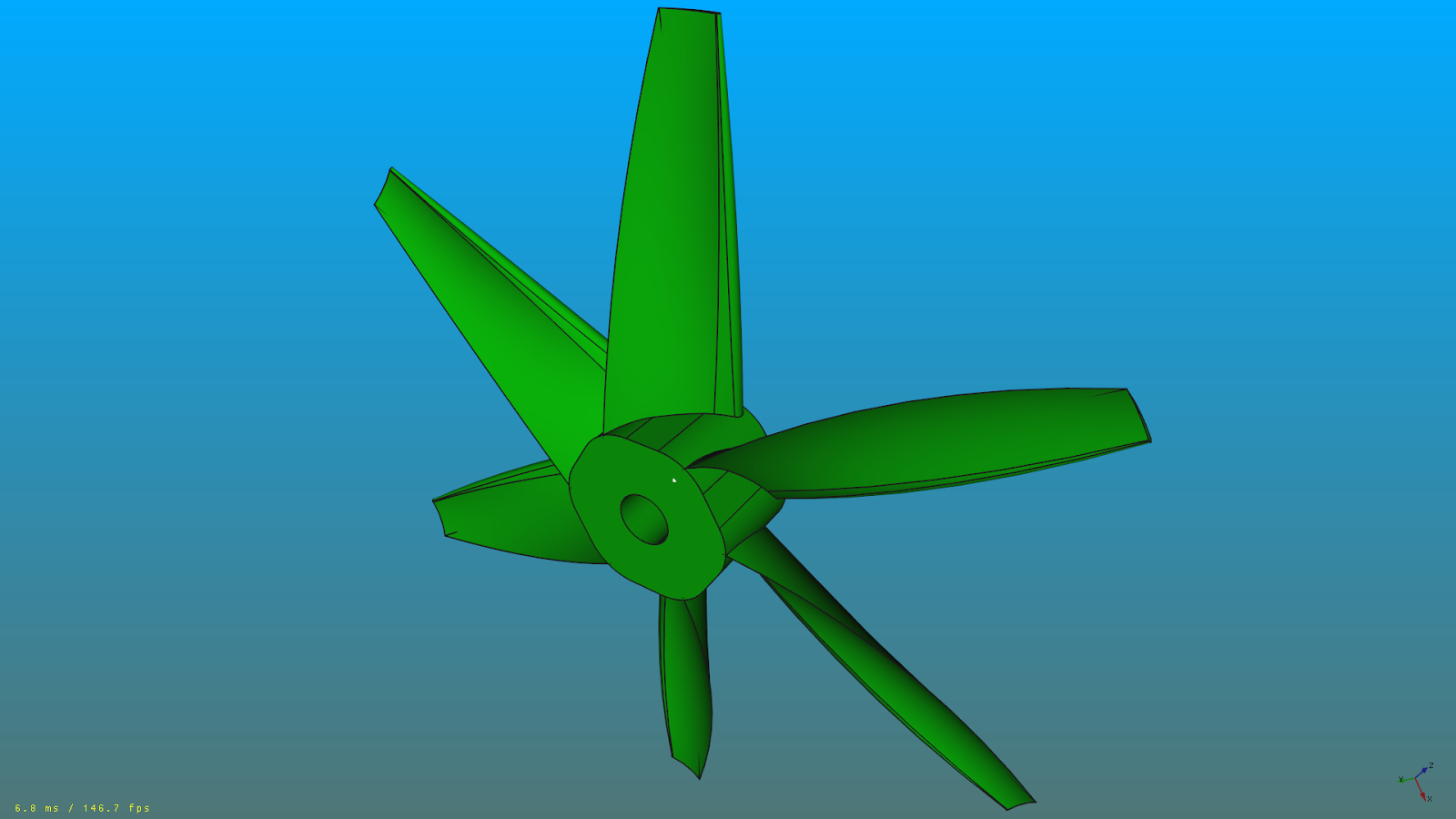

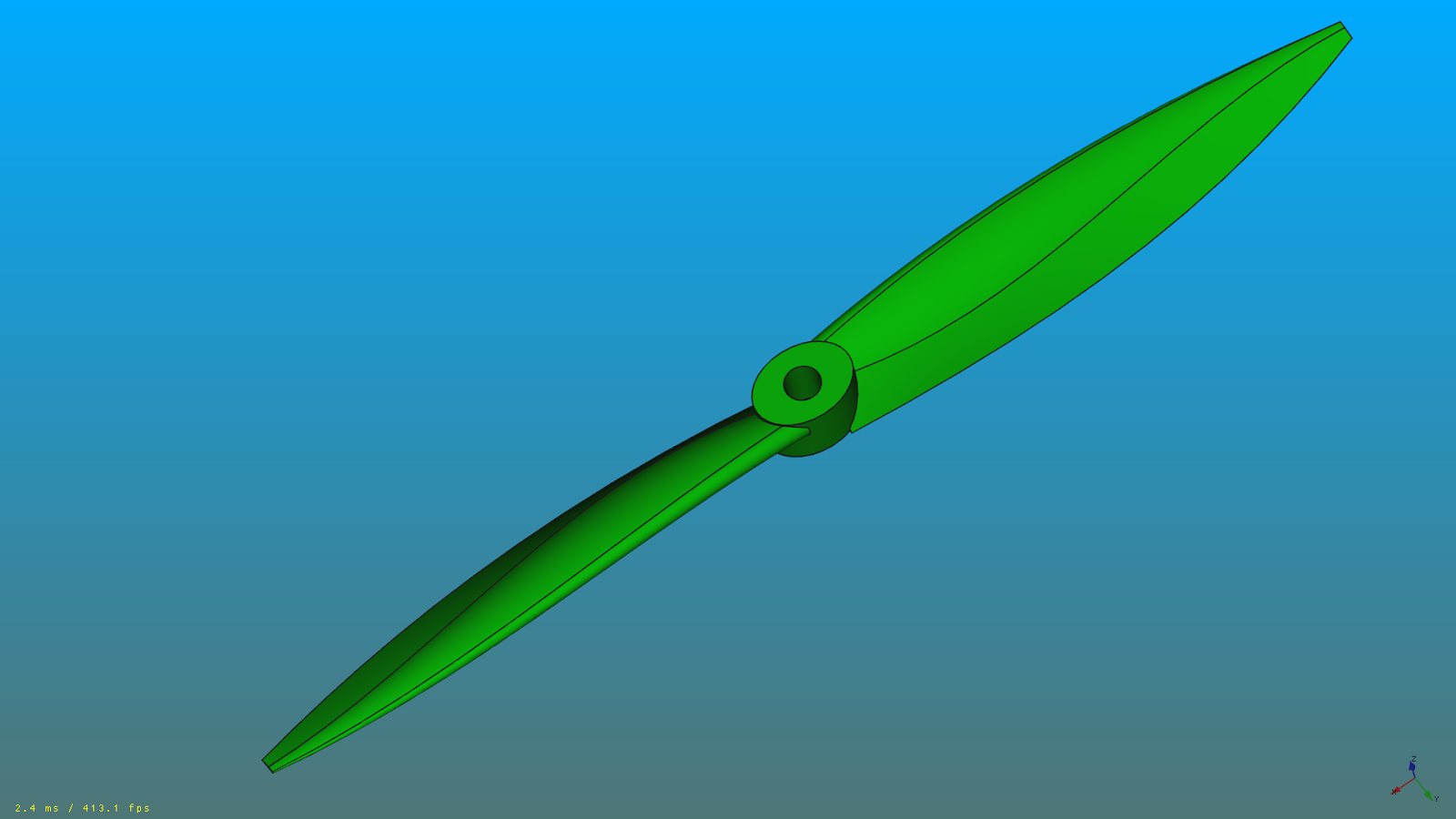

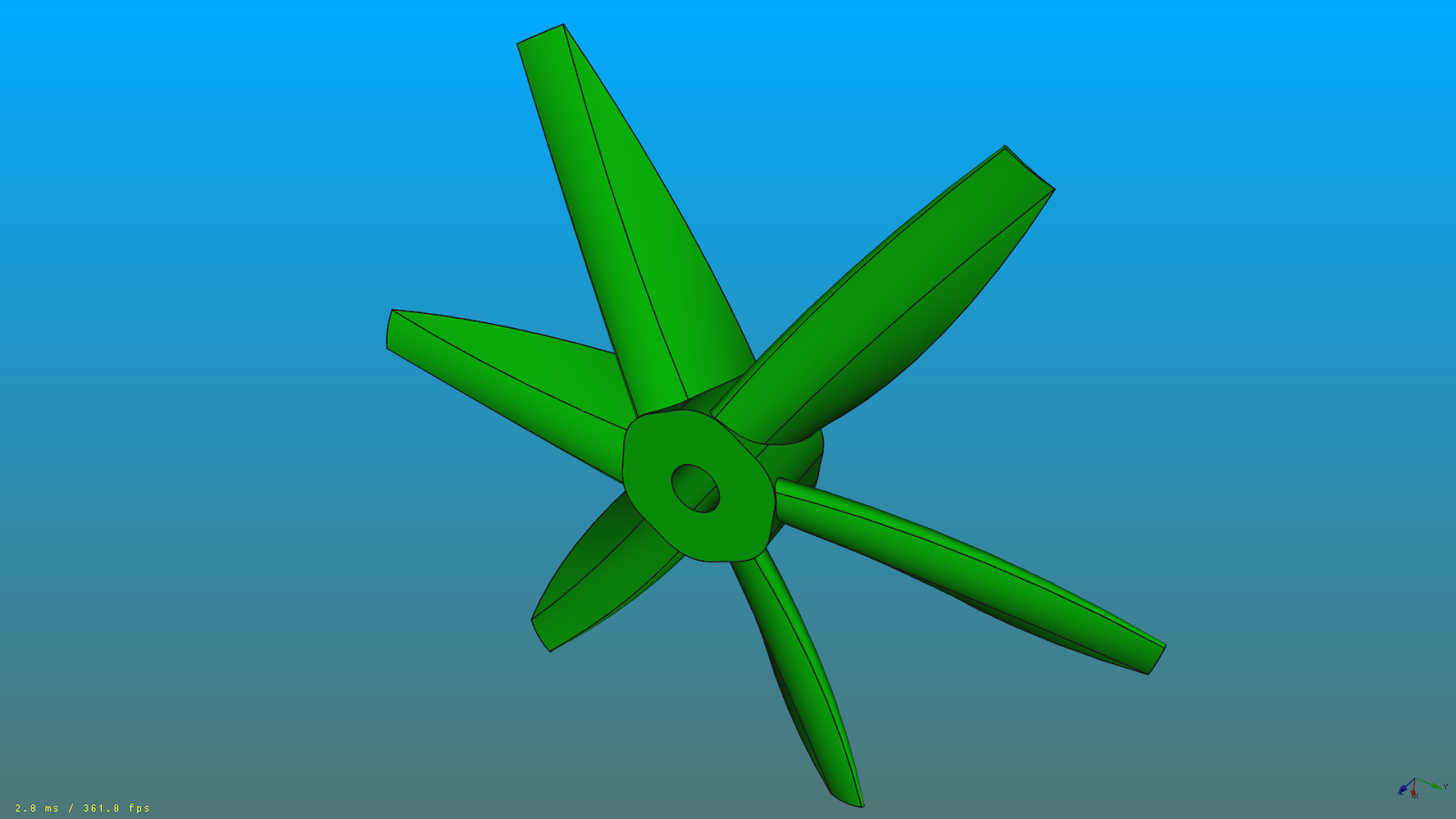

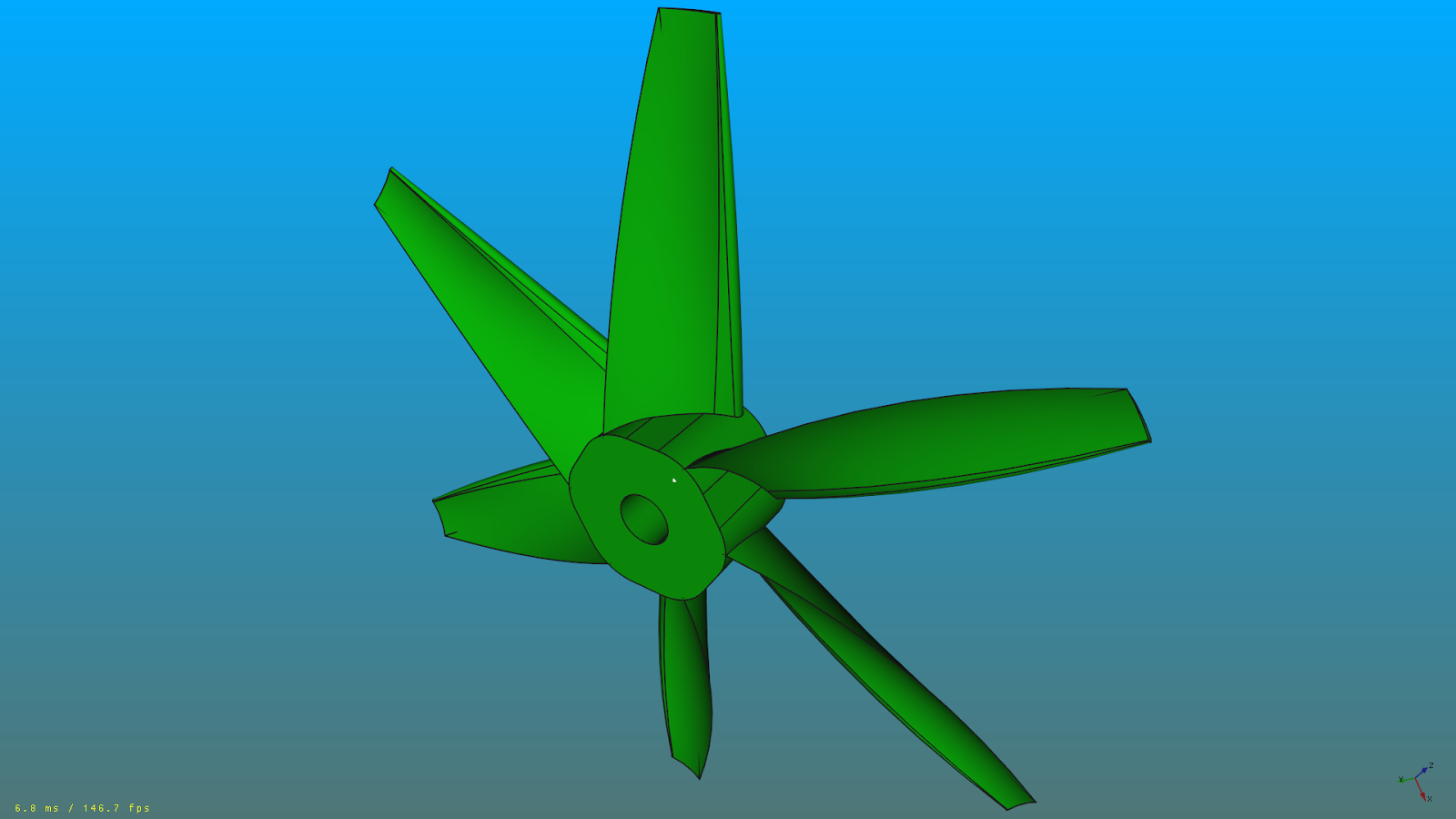

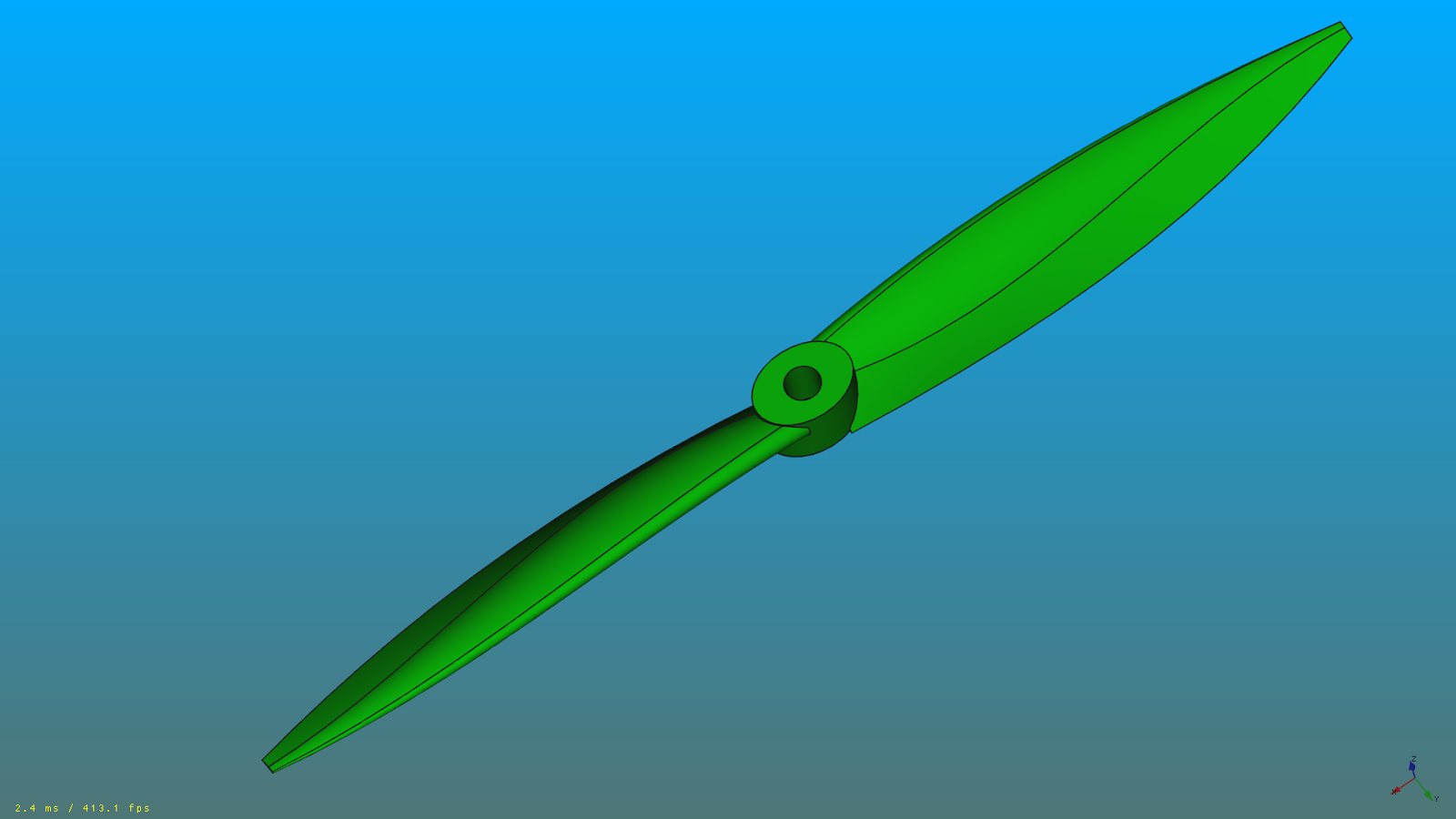

I recently got access to a 3D printer (BQ Hephestos2) and today I printed two propellers to test the strength of the PLA.

Six blades propeller, intended for high rpm motors (+25k rpm), tested to 10k rpm only:

Two blade propeller that could suit the airplane where the test is performed:

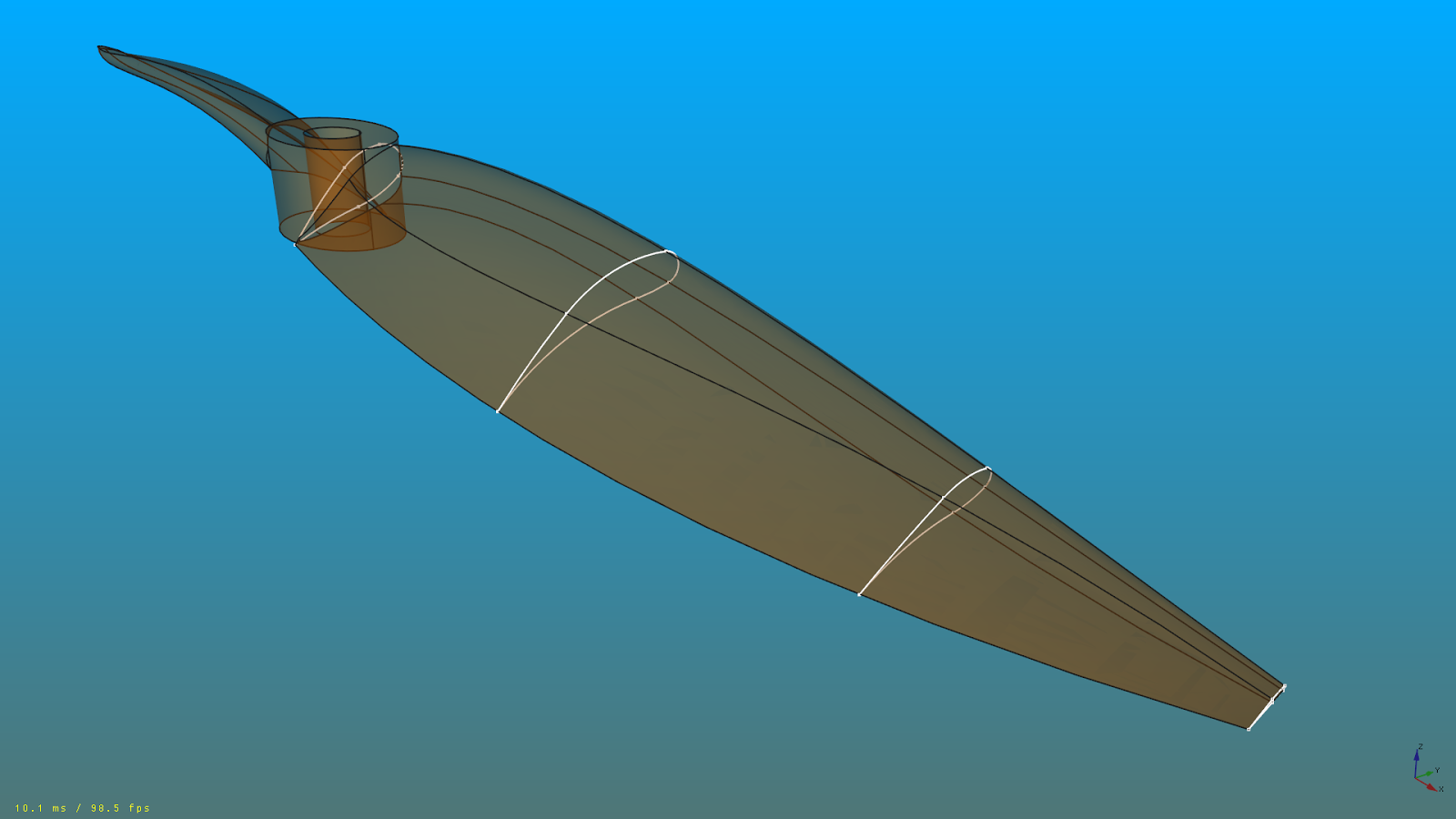

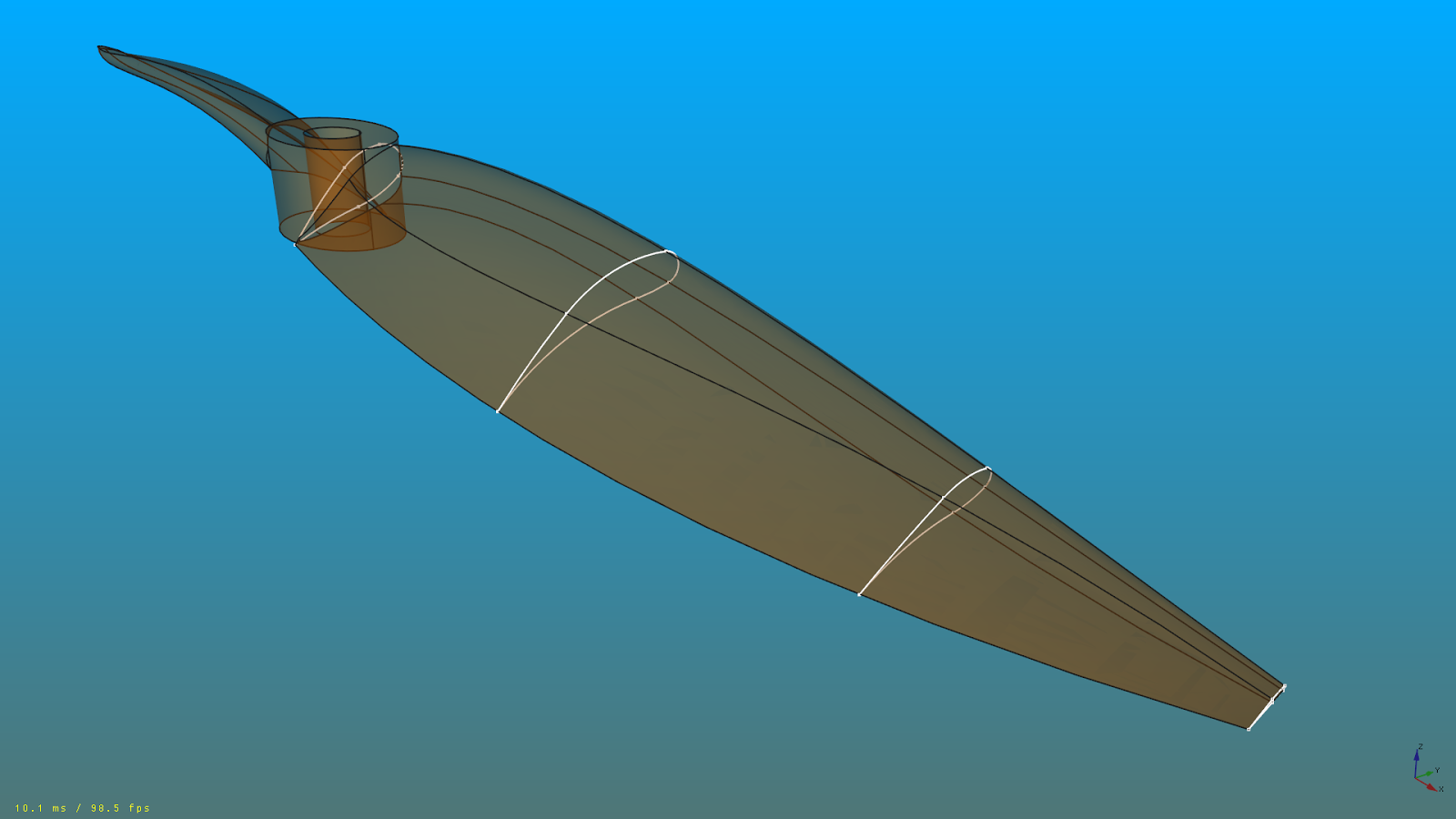

The blade is designed as a loft over several sketches (sections).

Video:

https://www.youtube.com/watch?v=LSFR4in7vMg

Surprisingly, they withstand the rpms and the larger one even produces noticeable thrust

Re: From FreeCAD To The Real World

Posted: Wed Feb 03, 2016 10:28 pm

by A_3

Great job!

By the way, excellent wind tunnel you have

Re: From FreeCAD To The Real World

Posted: Mon Jan 30, 2017 9:48 pm

by DeepSOIC

Recently I got myself a mini-lathe.

Milling attachments for it can be purchased, but they are a bit pricey. So I decided to make one with a bit of help from 3d printer.

This is the simplest model I've come up with. It allows me to re-use parts of lathe itself. The model is a creative process, so it's a total mess.

- lathe mill stand (sectioned).png (94.94 KiB) Viewed 7190 times

Printed of PLA with 20% infill and 3 perimeters. It has just enough rigidity to slowly mill some steel. Not great, but good enough for occasional milling.

- WP_20170130_23_35_49_Pro_.jpg (599.33 KiB) Viewed 7190 times

Thank you FreeCAD, Slic3r, Repetier-host and PrintBox3d

Now I need a vise....

Re: From FreeCAD To The Real World

Posted: Tue Jan 31, 2017 1:39 pm

by triplus

Yeah sooner or later you are tempted to produce something you designed in FreeCAD!

Re: From FreeCAD To The Real World

Posted: Sat Mar 18, 2017 1:43 pm

by rabbit

This is just a very simple thing: custom hooks to hang my self-made flyscreen frames when they're not in use.

The process, from having one topple over once again and realizing this can be solved to solution took probably about 30 minutes.

- hook.png (12.27 KiB) Viewed 6866 times

- hooks.jpg (156.14 KiB) Viewed 6866 times

Re: From FreeCAD To The Real World

Posted: Tue Jun 13, 2017 7:19 pm

by A_3

А simple sprinkler, 3D printed ABS plastic, for rear windscreen.

On the last picture you can see clean area, proof that the sprinkler works fine

Re: From FreeCAD To The Real World

Posted: Tue Jul 18, 2017 1:36 am

by bringThaRuckus

I watched this video, I love the actual printer. What model are you printing with?! I haven't built a printer yet. I just found someone who will print the parts for me. can most of your printer parts be replicated? smartrap! gotta have one.